- Home

- Food processing

- Slicers

LEGEND 350 LS

Back to the catalog

LEGEND 350 LS

Semi-automatic solution with electric motor for the blade and manual flywheel feed of the carriage, for a traditional cut- Made totally out of aluminium - Base oven-coated with food-safe, epoxy powders in Racing Red - Parts in contact with the product are in anodised aluminium - Special BS2 cured-meat gripper arm - Easy-to-dismantle stainless steel pusher arm - Exclusive sliding plate easy-to-dismantle for cleaning

Share:

This product appears in:

Watch the video

Product details

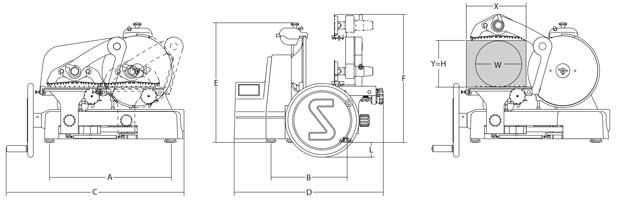

- Model: LEGEND LS

- ø blade: mm 350 - inch 14

- Motor: watt 450 - Hp 0,6

- Cut thickness: mm 3

- Run of carriage: mm 286

- Hopper: mm 350x330

- B: mm 612

- C: mm 382

- D: mm 893

- E: mm 749

- F: mm 601

- L: mm 643

- X: mm 74

- Y: mm 300

- H: mm 235

- W: mm 235

- Net weight: Kg 105

- HS-CODE: 84385000

Other news that may interest you

7th July 2023

How to clean your slicer: a practical guide to sanitation, maintenance and sharpeningA clean slicer is an efficient slicer. Learn the best practices for maintenance and which models are easiest to clean.

31st March 2023

How to choose a professional slicer: 7 key pointsLearn about 7 key points to help you choose the best model for your business’ needs.

Flywheel slicer

Manual slicer, manual flywheel slicer, small flywheel slicer, professional flywheel slicer, Italian flywheel slicer, flywheel slicer disassembly

The manual flywheel slicer is a fascinating machine that recreates the convivial atmosphere of a traditional Italian delicatessen. Upon entering a restaurant where it’s used within view, the customer is drawn to it, and will find it hard to resist asking for a slice. Its mechanism, however, only appears to be a simple one. In fact, the flywheel slicer is actually a highly complex machine. It’s a manual slicer without a vertical support upon which to rest the product to be sliced. When the flywheel is turned, the mechanism is engaged, with three coordinated movements: the blade, the carriage, and the plate, which advances based on the set portions, or rather the thickness of the slice to be cut. The mechanism is based on the ratio of the blade’s revolutions to the carriage’s advancement.

It’s a highly technical machine that requires extreme precision during both the manufacturing and assembly stages. With respect to inclined machines, which allow for the fast cutting of a single product, as well as quick alternation between various products, the flywheel slicer is recommended for tasks that involve cutting the same product over long periods of time.

The Legend slicer is a combination electric and manual machine, for which the operator chooses the operating mode. In electric mode, all the operator has to do is to collect the slice and place it in the collection area, as the blade rotates independently, and the carriage moves forward on its own. In manual mode, on the other hand, the operator can choose whether to operate the carriage manually, while allowing the blade turn electrically, or else to operate both the carriage and the blade manually. Being both manual and electric, the slicer is equipped with a vertical product support for safety reasons. The inclusion of a backing was a practical choice, as it allows the operator to proceed without performing preliminary tests, which result in discarded slices. When the manual function is enabled, however, the vertical product support moves, and the plate advances based on the desired thickness. Like with all the manual machines, the product does not come into contact with any surface during the cutting phase.

While the Legend slicer’s red colour is reminiscent of vintage slicing machines, it is not simply a remake of an older model, but is rather meticulously designed with entirely new mechanisms and technologies. The Legend even boasts a unique feature not found on any other model on the market: it’s the only flywheel slicer from which the carriage can be entirely detached for easy cleaning. This mechanism, which allows the flywheel slicer to be conveniently disassembled, was meticulously designed by Sirman’s engineers, and is protected by two registered patents.

Like many Sirman products, the professional flywheel slicer is conveniently sized for compact spaces, and can fit atop a 70 cm table.

ThisItalian flywheel slicer is reminiscent of the attentive, elegant, high quality food service of the past. While the machine’s refined movements and carefully crafted aesthetics make it a show-piece for any food service enterprise, its meticulous design and construction also guarantee extremely high performance standards, regardless of its appearance.

Other products that may interest you

12

NEWSLETTER

Promotions and news, directly in your email